Bored pile

Soletanche Bachy presents its full range of piles: bored piles.

LDA (Large Diameter Auger) piles, more commonly known as bored piles, are used mainly as part of the foundation works for major structures or retaining structures.

.

A pile is defined as a structural element positioned in the soil to transfer loads and limit distortion. There are no limits on its slenderness ratio. Piles may be uniformly straight, threaded, flared and under-ream, or prefabricated.

Piles may be used in isolation or in groups. They can also form a mixed, continuous, secant or tangent piled curtain retaining wall or a composite curtain wall like a Berlin-type wall or similar. Piles are also used as plunge column (or stanchions) for structural incorporation into a building with basement levels.

Columns of this type are installed before any earthworks begin and can take part of the load imposed by the superstructure when it is constructed in parallel with the basement levels. They may be battered where specified in the installation standards.

The main types of pile include:

- Bored (LDA) piles,

- Continual flight auger (CFA) piles

- Deep piles

- Displacement and driven piles

- Displacement pile, Screwsol® or rotary displacement (CHD) piles type

- And micropiles

Bored piles and barrettes differ in terms of their right cross-sectional shape:

Large-diameter bored (LDA, Kelly) piles are the most traditional and common form of piling worldwide. They are capable of supporting very high loads and coping with complex soil conditions. They are used chiefly in the foundations of major structures, but may also be used to provide support within secant pile walls.

- Piles are circular in cross-section.

- Square, rectangular, T-profile, L-profile or any other similar configuration are referred to as barrettes. The barrette methodology and its advantages are detailed in the description of the diaphragm wall technique

What are the advantages of this technique?

Cost-efficient piles with a higher load-bearing capacity ratio

Piles can be constructed on land or from floating platforms

A range of interchangeable tools is available to cope with different types of terrain

Soletanche Bachy’s advantages

- The ability to analyse drilling rigs as the basis for optimising design parameters and confirming soil characteristics

- The ability to design and manufacture special tools

- A modern and versatile fleet of more than 180 LDA piling rigs, 50 crane ropes, 280 crawler cranes and cable excavators

- A laboratory dedicated to the development of drilling muds and concrete formulations

- Dedicated construction work quality control software

Implementation

The LDA technique requires the use of powerful hydraulic piling rigs which can use interchangeable attachments such as augers, buckets or core barrels.

These tools can cope with all types of granular or cohesive soils, including rock up to a compressive strength of 100MPa:

- Augers for cohesive and dry non-cohesive soils

- Digging buckets for granular strata

- A combination of rock augers and core barrels for harder strata

LDA piles use a temporary steel casing to support unstable strata and ensure safe working conditions at pile boring platform level. The casing is installed by the piling rig using a range of techniques developed for different soil types: vibration, oscillation or rotation. After concreting, the casing is removed immediately for re-use, although in some applications it may be left in place to provide protection or reinforcement.

As with diaphragm wall, carrier fluids such as bentonite or polymer may be a more effective way of stabilising a deep pile bore than using a longer casing.

The general principle here is to maintain a positive hydrostatic fluid load in the bore above groundwater levels. The bore excavation phase is followed by substitution or removal of the drilling mud, installation of steel reinforcement, and concreting of the pile. Concreting begins at the bottom of the bore using tremie pipes.

Bored piles generally take the form of cast-in-situ concrete reinforced with a steel rebar cage.

However, reinforcement can also be provided by prefabricated concrete and/or steel elements in preparation for the installation of retaining walls (e.g. Berlin-type walls) or plunge columns.

Features

- Bored pile diameters commonly range from 600 mm to 3.6 metres, but are constantly increasing, and can in some cases be up to 5 metres.

- Depths of 100 metres are also becoming relatively commonplace on land suitable for this type of technique.

Soletanche Bachy has developed highly sophisticated, high-performance machines with onboard electronics to guarantee reliable construction of piles and barrettes to cope with all aggregate diameters and/or concreting conditions.

– The inspection measures for barrette construction are detailed in the description of the diaphragm wall technique.

– The drilling rigs of the Soletanche Bachy fleet are all fitted with verticality measurement and parameter acquisition systems directly linked to the Z-Lyze® system developed by Soletanche Bachy.

Zetta-Lyze® provides real-time collection and processing of data generated by the acquisition systems embedded in its fleeting machinery.

Execution controls and monitoring

Did you know?

Soletanche Bachy uses a range of complementary techniques to improve the performance of standard LDA piles.

Under-ream piles

Under-ream, or “bell”, piles are perfectly suited to providing exceedingly high-bearing capacities in stable cohesive strata. Under-reaming of piles to produce enlarged bases has traditionally been used to enhance end-bearing capacity and provide economical support for structural mega-columns. The Group manufactures its own top-hinged tools that are operated mechanically during excavation. They can produce piles with shafts up to 2.4m and enlarged bases up to 7.2m (3 times the shaft diameter).

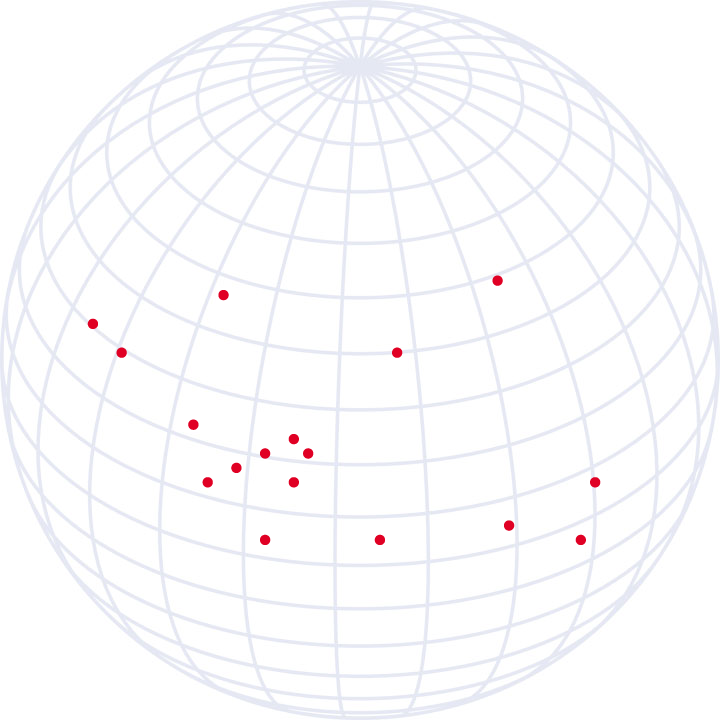

50 pays d’implantation

Soletanche Bachy is a world leader in foundations and soil technologies, operating in 60 countries via a network of 80 subsidiaries and branches. The Group delivers the full range of geotechnical processes and provides innovative, effective solutions as either a lead or specialist contractor for turnkey projects with a geotechnical focus or specialist works.

Soletanche Freyssinet

Soletanche FreyssinetThis website uses cookies to ensure you get the best experience

Learn more