Trenchmix®

Cost effective continuous walls, and a lot more!

The Trenchmix® process is a very effective solution for cut-off walls but can also have many other uses. Find out more about Soletanche Bachy Deep Soil Mixing offer.

Trenchmix® is a Deep Soil Mixing process that produces continuous trenches of soil mixed in situ with a binding agent.

This binding agent can simply be cement, or a blend of cement with other products such as lime, fly ash or slag.

Soil-cement mix trenches are created using a specially adapted trenching machine designed to:

- Extract very little volume of in situ soil

- Be capable of incorporating the binder by dry or wet method

- Mix the soil in-situ with the binder on full height of the blade.

The Trenchmix® process creates in-situ continuous walls that may be described as lineic (viewed from above) or surfacic (viewed in elevation). When used alone, a continuous Trenchmix® wall can be used for cut-off application. Once structurally reinforced, a Trenchmix® wall can form a retaining structure which can be used as support of excavation. When used as a network of parallel or secant trenches, Trenchmix® walls can be used for soil improvement applications.

The soil-cement mixture can achieve an average compressive strength of around 3 MPa and hydraulic permeability valuesbelow 10-6 cm/s.

Applications

- continuous cut-off walls

- Confinement cut-offs to contain polluted soil and reduce percolation flow rates

- Consolidation of embankment slopes using parallel shear walls

- temporary support of excavation in combination with structural reinforcement in the form of metal profiles, tubes and/or columns

- Improvement of being capacity of weak or compressible soils industrial warehouses, storage areas and linear structures, such as rail and motorway embankments

Wall dimensions

Wall thickness corresponds to the width of the blade used: between 350 mm and 500mm

Wall depth is governed by blade length.

What are the advantages of this technique?

Generates only small amounts of spoil

Not particularly environmentally intrusive

Lower consumption of resources (low use of water and no need of aggregates)

Fast and efficient

Continuous, seamless treatment

Excellent final hydraulic permeability. Better than a bentonite cement wall

Very good erosion resistance

Compatible with low headroom conditions

When in operation, generates no vibrations on nearby existing structures

Soil-cement mix l is homogenous on full height of the trench

Soletanche Bachy’s advantages

- In-depth knowledge of the properties of the soil-cement mixture, allowing us to offer special formulations that are optimised and specific to each site

- An in-house laboratory to deliver a specific response to the needs of each project

- A specific design method for soil improvement applications

- Two machine versions (trencher and hydraulic excavator), the choice being made to suit to the type of project

Implementation

This process offers a choice of two techniques. That choice will be determined by the nature of the soil, the type of work to be carried out and the moisture content of the soil.

- wet method

The binder is introduced in the form of a liquid made of binder and water

- Pre-trench on the platform to control a the spoil outflow

- Grout is prepared in a batching plant and pumped to the trencherThe in situ soil is destructurated while binder is introduced to form the mixture. Mixing is brought by the action of several blades passing at high velocity inside the mixture.

- The dry method

The binder is introduced directly into the trench in powder form

- The platform is pre-trenched to:

- Receive the binder

- Control the spoil outflow

- Binder is first introduced in the pre-trench.

- When passing afterwards, the blade of the trencher destructurates the soil while incorporating the dry binder. An addition of water can be made when needed. Mixing is brought by the action of several blades passing at high velocity inside the mixture.

– Wet method: checks on the properties and composition of the cement grout

– Dry process: quality control of the cement used

– Continuous monitoring of tool positioning

– Profile tracking with depth adjustment where necessary

– Properties of the soil-cement mixture are checked by wet grab samples

– A dedicated supervisory system provides simultaneous real-time checking of soil/binder homogeneity and the quantity of binder injected

Execution controls and monitoring

Did you know?

TrenchmiXS

Soil improvement for electrical tower foundation

To ensure the safety of its distribution grid in the aftermath of the 1999 storms in France, RTE (Réseau de Transport d’Electricité) initiated a campaign to identify and secure hundreds of electric towers in France. Amongst the various solutions possible one technique involved the construction of soil-mixed reinforcement blocks around each concrete footing of a tower while still in use. To do so, a low headroom Trenchmix® tool mounted on a hydraulic excavator was used. This equipment is called TrenchmiXS, XS meaning “extra small”.

The Deep Soil Mixing family of techniques also includes these processes in addition to Trenchmix®:

- The Colmix® process

- The Geomix® process

- The Springsol® process

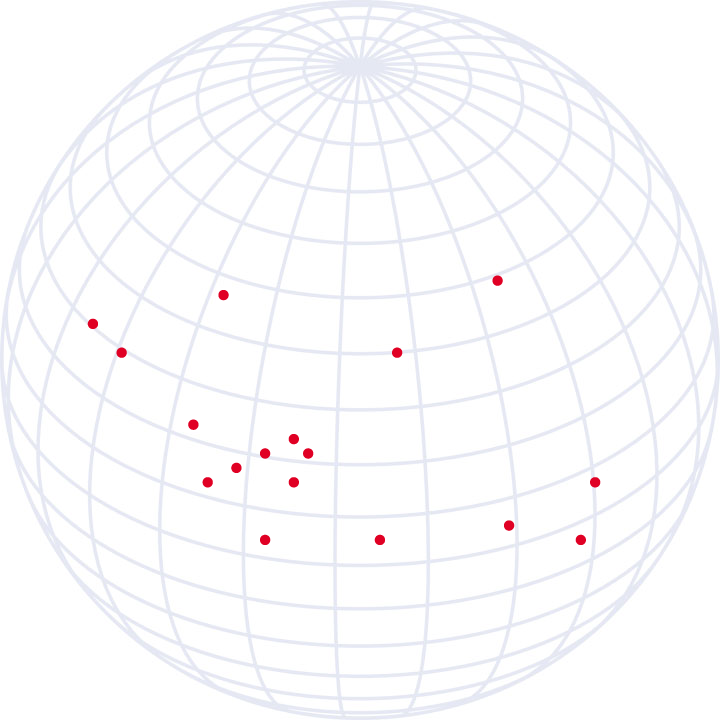

50 pays d’implantation

Soletanche Bachy is a world leader in foundations and soil technologies, operating in 60 countries via a network of 80 subsidiaries and branches. The Group delivers the full range of geotechnical processes and provides innovative, effective solutions as either a lead or specialist contractor for turnkey projects with a geotechnical focus or specialist works.

Soletanche Freyssinet

Soletanche FreyssinetThis website uses cookies to ensure you get the best experience

Learn more